EASY BINDER

the one touch binding solution…..an introduction

Offered by

Aditya Frontline Marketing

Features:

• Punches paper documents of up to 2 inch thickness

• Binds up to 2 inch thickness

• Fully automated punching

• Fully automised binding

• Rapid punching and binding within 30 seconds respectively

• Automatic release of appropriate size consumable

• Low operating costs

• Digital operation

• Table top use

Product synopsis:

The ABC Easy binding equipment is a unique sturdy, durable, efficient and convenient binding process that is otherwise called Easy binding. The process involves puncturing of a hole into the total number of sheets desired to be bound. The punched paper is also simultaneously judged by the machine for selection of an appropriate consumable and the same is ejected by the equipment to the collection tray. The consumable is then inserted into the paper and moved to the binding point, where the binding needle moves into the consumable slotted into the punched hole. Hence, a heating process takes place at both the ends of the tubular consumable giving it a riveted finish at both ends.

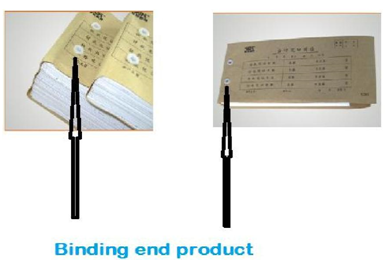

Besides being ideal for presentations, this process also is a convenient, cheap and efficient method of binding documents for preservation. The operation of the equipment does not take longer than 20 seconds and is digitally operated. The other advantage of this equipment is that it has no limitation in operation time permitting large volume of binding to be completed over a shorter duration. The white material indicated by arrows in the below picture is the bound end product.

Consumable:

The consumable for this product comes in the form of a specialized plastic straw designed to withstand heat. This comes in standard lengths of 50cms and one straw at a time is inserted into the equipment at the slot provided for. The equipment while undertaking the punching process also simultaneously gauges the thickness of the paper and automatically cuts the straw to the requisite length. This cut straw is discharged into a collection tray and slotted into the punched area and moved to the binding section where heaters at either end rivet the two ends so as to lock the documents. An A4 document can be more than ideally be held together by two such riveted spines.

This process ensures minimum wastage and optimum utilization of the consumable making it a very economical and fast exercise with durability.

The machines generally come as automatic and fully automatic. Whereas in the former case the punched paper needs to be moved to the binding section (point 2 in above dig.), in the latter case the same is undertaken at the same point with the equipment automatically alternating between the punching and binding process.

Advantages of using a Easy Binder:

Convenience of operation and speed: An absolutely hassle free operation which only warrants a mere placingof the total number of sheets that need to be bound. The entire operation is, hence, automatically undertaken to be over in 30 seconds. A maximum thickness of 2 inches or an equivalent of 600 pages of 70 gsm paper can be undertaken at one go. This eliminates the hassle with conventional bindings which warrant repeated punching of a number of sheets (max. 20 at a time) to arrive at the total number of sheets to be bound. It also eliminates the need to have a dedicated person to operate and can be compared to a coffee dispenser for its ease of operation.

Un-sized Binding: Easy binding does not have a limitation on the size of the document to be bound, exceptthickness (2 inch max). This enables documents of various sizes to be bound together through a very simple process that does not warrant a methodical aligning of the papers.

Optimum utilization of consumable : The consumable which comes in the form a hollow straw in lengths of50cms, made of polyurethane, is selected by the equipment in proportion to the number of sheets to be bound for every perforation. This totally eliminates wastage and ensures optimum utilization of consumable leading to considerable savings. Superior quality of the consumable ensures durability and strength.

Minimal binding points: Conventional binding necessitates punching of holes right through the entire marginof the page in order to hold the documents together. With Easy binding a document can be held firmly with a mere single binding point. This enables more space on the paper for printing.

Minimal induced break-down: Break-down with all conventional binding equipments is a result of thesignificant human intervention involved in the punching and binding processes. This is eliminated in this equipment as the punching and binding functions cannot involve human interference. Besides, the equipment cannot be forced to work which also rules out the aspect of over use during normal working hours.

Low running costs and higher productivity: Running costs generally relate to consumption of consumablesand related operating costs. With the consumable being selected by the equipment and that too in one single size, the aspects of erroneous selection of consumable are totally eliminated. Besides, with the process being completed in a fraction of time (20-30 seconds) in comparison to conventional binding (500 sheets binding could take up to 15-20 minutes), larger number of bindings can be effortlessly completed in quicker time.

Savings on invaluable space: A significant aspect of cost that adds to overheads is space. Most organizationsallot invaluable space area towards storage of records. With uneven sizes of the bound documents this leads to haphazard storing that occupies a lot of space as a result. With Easy binding’s ability to compress and bind besides uniformity, it leads to proper stacking of documents. With Easy binding, conventional methods of storing documents such as box files, hard cover files etc which occupy lots of space can be done away with and re-used.

Savings on stationery: With the advent of Easy binding, the advantage of customized binding comes to thefore. Therefore, normal filing stationery such as box files, hard cover files need not be freshly purchased; besides, it enables the re-use of the existing filing methods. This tantamount to a substantial saving in office stationery.

Areas of use:

– Educational institutions – Fee’s receipts, challan, binding textbooks, notebooks, project work

– Banking & Financial Institutions – preserving vouchers, challan ,reportsetc.

– Publishing Industry – for proofs and other bindings

– Studios for album making

– Companies- for project presentation, board meetings etc.

– Factories – for filing in process records

– Security Organizations – for filing relevant records for preservation

– Offices – filing of records

– Training institutions – for binding training material

– Hospitals – preservation of records

– Railways, Airlines, shipping and other transportation means

– Electricity boards

– Water and sewage departments

– Registration offices

– Courier offices

– Legislative council for preserving minutes

– Print media

Areas of application:

– For document presentation

– For document preservation

– Binding of paper of any form and thickness

– Re-enforcing bound documents

– Alternate for conventional filing of records

– Manuals, inappropriate size documents

– Swing documents

– Binding documents that otherwise consume lot of space

– Rapid binding

Advantages:

Fast, simple and automized process involving minimal manual interference

Durable and sturdy

Optimum and accurate utilization of consumable amounting to low operating costs

Fully digitized settings ensuring accurate punching and binding

Automized functioning ensures higher productivity

Punches and binds paper of any form and thickness

Unlimited usage under standard conditions

Minimal power consumption

Models Offered:

AUTOMATIC BINDING MACHINE

FULLY AUTOMATIC BINDING MACHINE

To learn more about our solutions Contact Us info@adityafrontline.com

+91 72999 69630 / 72999 69650 / 98410 94838