BRANDS

MULTI FUNCTION DEVICE (MFD)

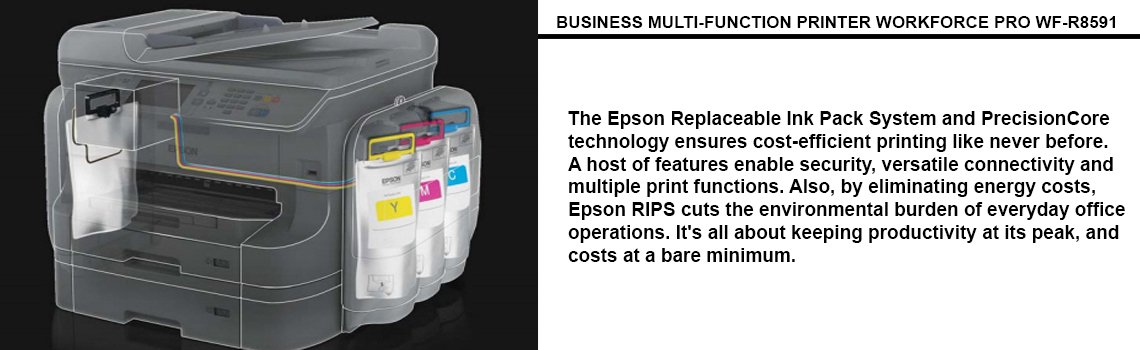

A Multi-Function Device (MFD), is an office equipmentthat incorporates the functionality of multiple devices in one. A modern day essential product in office automation, these are available in standalone portable units of minimum configurations to high-end standalones that consists of innumerable features that permit high speed printing and networking amongst others. MFD’s help one do away with the necessity of having multiple equipments to cater to the below applications

- Fax

- Photocopier

- Printer

- Scanner

Digital Duplicator

A Printer-Duplicator, also known as a digital duplicator, is a printing technology designed for high-volume print jobs (20 copies or more). Printer-Duplicators can provide a reliable and cost efficient alternative to toner-based copiers or offset printing equipment.

The Printer-Duplicator begins by digitally scanning the original and then transferring it to a master template through a thermal imaging process. Then the master is automatically wrapped around a print cylinder, where the ink is drawn through the perforations in the master creating the print.

Printer-Duplicators are known for very high speed in comparison to other printing methods. They are able to produce anywhere from 60 to 180 prints per minute, while maintaining a per page cost that can be as low as few paisa. They are also considered very reliable because they do not use heat or copier components, such as toner.

How digital duplicators work

Like the stencil machine, digital duplicators have a stencil (called a master), ink, and drum—but the process is all automated.

A master is capable of making 4000–5000 prints

- The original is placed on a flat-bed scanner or feed through a sheet feed scanner depending on the model.

- The image is burned onto the master material that is coated on one side, in a series of small holes by the thermal print head.

- As the new master is burning it is stored while the old master is removed.

- There is a clamp plate on the drum that opens by motor. The drum turns and the old master material is feed into the disposal rollers and into the disposal box.

- The new master is fed into the clamp which closes, the drum is turned pulling the master onto the drum.

- The outside of the drum is covered in screens and the inside is coated in ink. The screens make sure the ink is regulated.

- The paper is fed to the drum and the ink only comes through the master material where there are holes.

- When the start button is pressed the image is scanned into memory by reflecting light off the original and into a CCD.

To learn more about our solutions Contact Us info@adityafrontline.com

+91 72999 69630 / 72999 69650 / 98410 94838